MIL-PRF-49291D

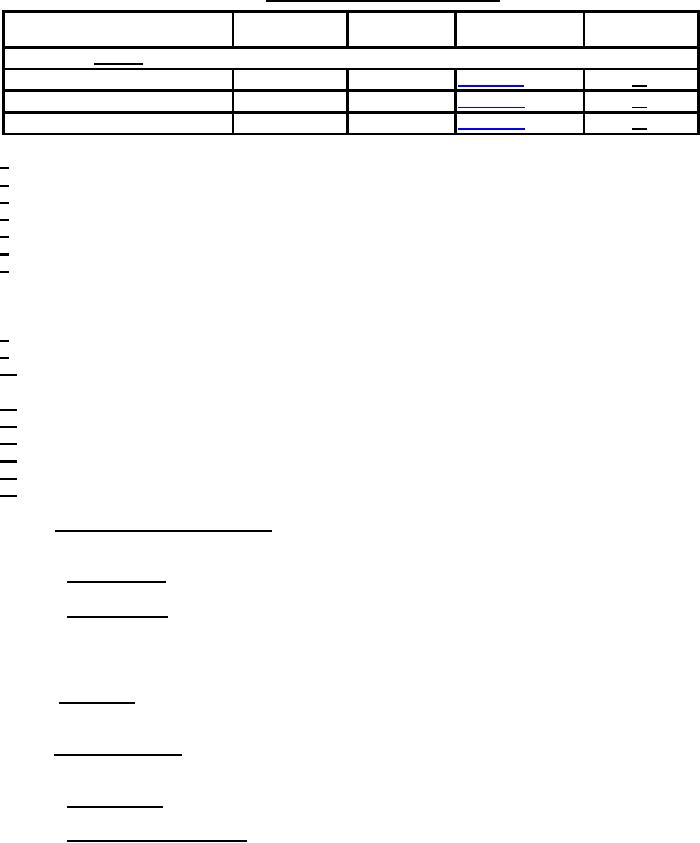

TABLE I. Qualification inspection (continued).

Requirement

Test

Applicable test

Specimen

Inspection

paragraph

paragraph

document

length

Group IV

Thermal vacuum outgassing

16/

Odor

16/

Toxicity

16/

1/

The visual and mechanical inspection shall only be conducted on a 2 m section of each sample unit.

2/

A specimen cut from each 2.2 km sample unit shall be used.

3/

Type I fiber only.

4/

Fiber parameter test.

5/

Type II fiber only.

6/

The same 2.2 km sample units used in the visual and mechanical inspection shall be used.

7/

Group I tests may be performed on shipping spools, measurement spools or in a loose coil. If fiber

parameter tests are conducted on fiber on shipping spools and the results of any fiber parameter test

is not within specification, all fiber parameter tests shall be conducted on fiber on measurement

spools or in loose coils.

8/

One sample unit shall be used for this test.

9/

A specimen cut from each 2.2 km tensile proof test sample unit.

10/

The fiber length shall be > 200 m for residual gamma testing and > 20 m for prompt gamma and

neutron testing from each specimen. Each specimen shall be tested at one temperature.

11/

Specimens cut from each 2.2 km tensile proof test shall be used.

12/

The same specimens used in the fluid immersion aging test shall be used.

13/

The remaining portion of the three 2.2 km sample units used in the tensile proof test shall be used.

14/

Group III environmental tests shall be conducted with each 2.2 km specimen in a loose coil.

15/

The same specimens used in the thermal shock test shall be used.

16/

Finished material from a fiber sample.

4.6.1 Inspection of product for delivery. Inspection of product for delivery shall consist of group A

inspection.

4.6.1.1 Unit of product. A unit of product shall be 1100 meters minimum.

4.6.1.2 Production unit. The production unit shall consist of the number of units of product produced

on the same production line or lines, and offered for inspection at one time. All of the units of product in

the production unit submitted shall have been produced during the same production period with the same

materials and processes.

4.6.1.3 Specimen. A specimen shall be an individual length of fiber cut from the sample. Unless

otherwise specified, a minimum of the specimens shall be inspected and tested from each sample.

4.6.2 Group A inspection. Group A inspection shall consist of the inspections and tests specified in

table II.

4.6.2.1 Sampling plan. Group A inspection shall be performed on 100 percent of delivered product.

4.6.2.2 Disposition of sample units. Sample units from which a specimen has failed any of the group A

inspection tests shall not be delivered on any order.

11

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business