MIL-PRF-49291D

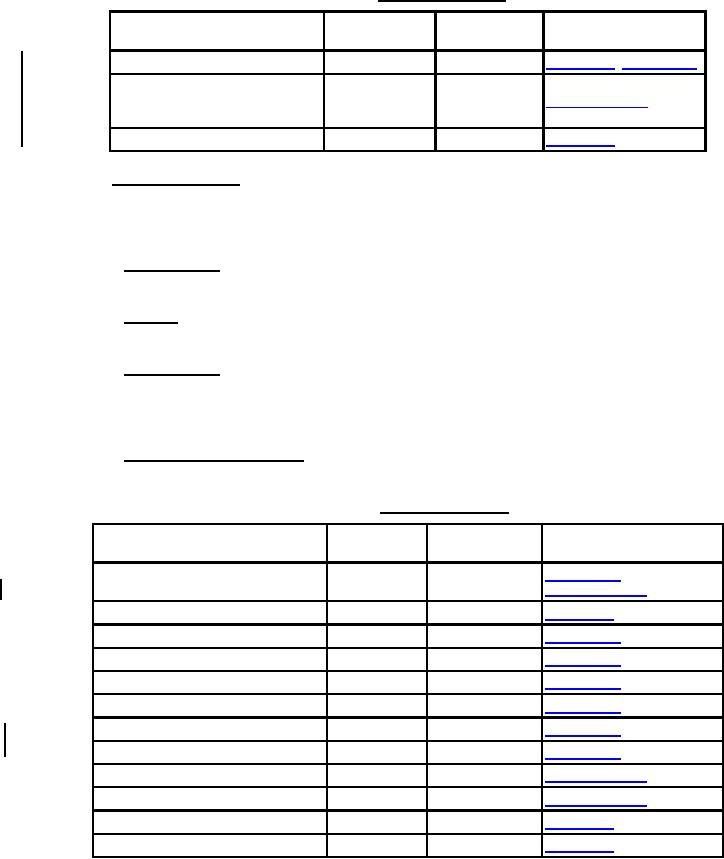

TABLE II. Group A inspection.

Requirement

Inspection

Test paragraph

Applicable test document

paragraph

Visual and mechanical inspection

Attenuation rate

Type I

Type II

Measurement 2106

Attenuation uniformity

4.6.3 Group B inspection. Group B inspection shall consist of the inspections specified in table III.

Group B inspections shall be made on units that have passed the group A inspection. The maximum time

from the end of one group B inspection to the beginning of the following group B inspection shall be not

greater than 24 months.

4.6.3.1 Sampling plan. Group B inspections shall be performed on 100 percent of product covered by

each specification sheet.

4.6.3.2 Failures. Production units in which one sample unit has failed a group B inspection test shall

be rejected.

4.6.3.3 Rejected units. If a production unit is rejected, the supplier may screen out the defective units

of product (if possible), and resubmit for reinspection. Resubmitted production units shall be inspected

using tightened sampling. Such production units shall be separate from new production units, and shall

be clearly identified as reinspected production units.

4.6.3.4 Disposition of sample units. Sample units from which a specimen has failed any of the group B

inspections shall not be delivered on any order, even though the production unit submitted is accepted.

TABLE III. Group B inspection.

Requirement

Inspection

Test paragraph

Applicable test document

paragraph

Mode field diameter

TIA-455-167 or

Core diameter

Cladding diameter

Cladding ovality

3.5.1.2.5

4.7.2.1.5

Core ovality

Core-to-cladding offset

3.5.1.2.6

Coating diameter

Overall coating concentricity error

Material inspection

Numerical aperture

Cut-off wavelength

Tensile proof

12

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business